Many of you will recognize this sentence, and you will hear it countless times over the next few days...

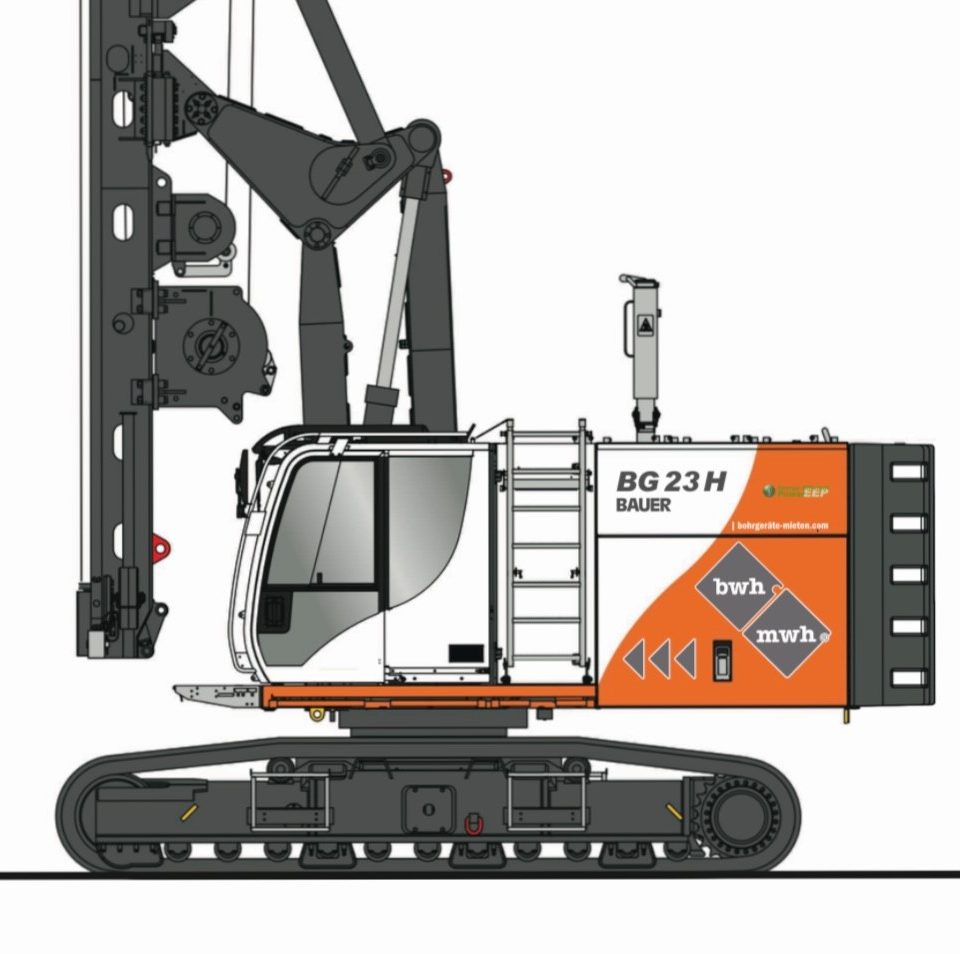

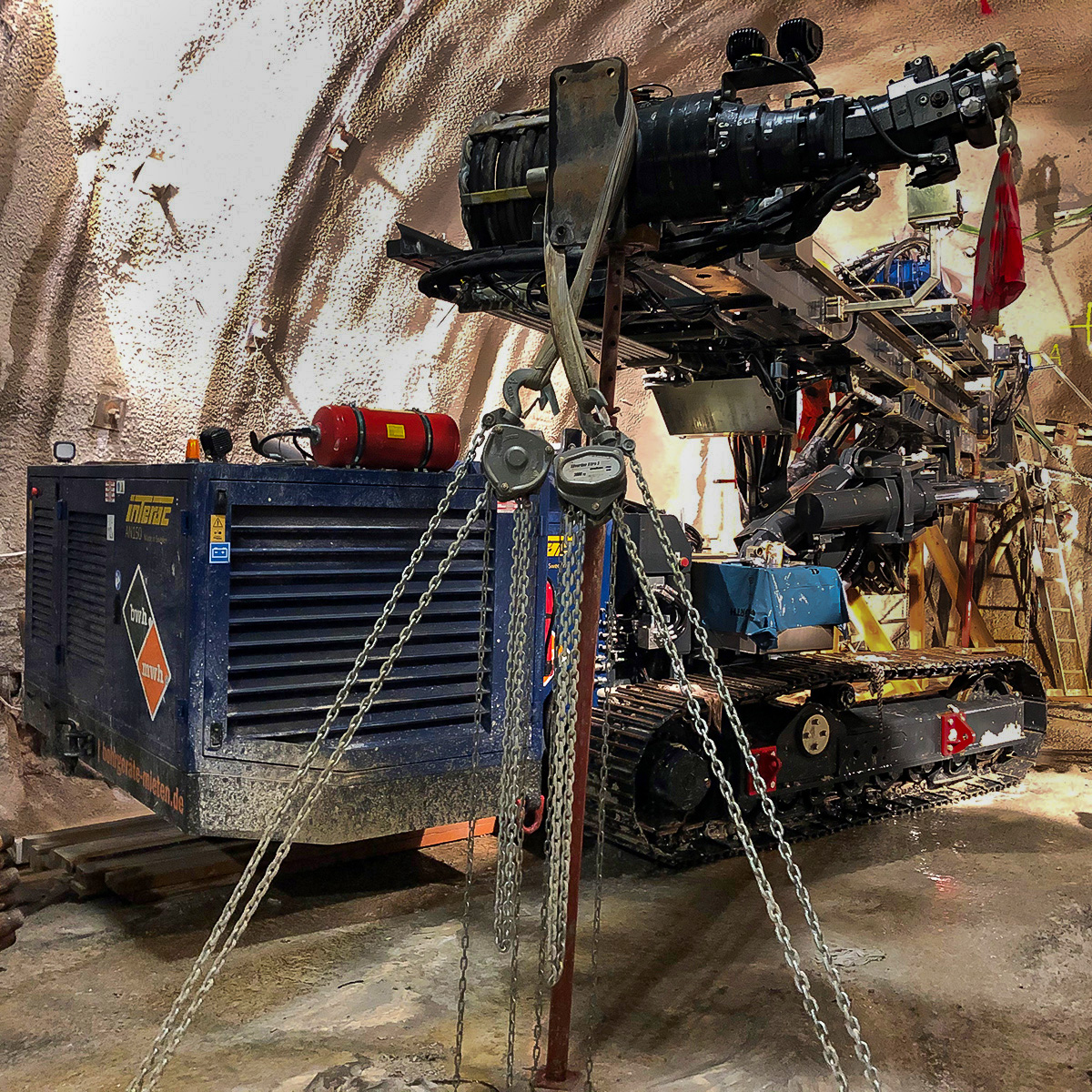

LIEBHERR LB16 goes on a diet and can fly

In the middle of the baroque quarter in Dresden, the former Hotel Stadt Leipzig is being renovated. The building complex will later be called „Heinrichshöfe“. The work required a rotary drilling rig, which could not be transported directly to the site via the access roads due to its size. The only option was to lift it over the facade into the rear courtyard using a crane. But the floor space available for the crane was also limited. The largest feasible crane, a 400t unit, could „only“ lift a load of approx. 25t due to the projection.

However, even our smallest drilling rig suitable for the upcoming work, the Liebherr LB16-180, weighs over 50t. Our client, the special civil engineering company Heinz Lange from Ottendorf-Okrilla, presented us with this assignment and it was an exciting challenge for our engineers to put the appliance on a diet. Kelly bar, rotary head and counterweight were of course the first measures. This was followed by the elaborate dismantling of the leader (mast). When all these efforts did not achieve the desired result completely, even the diesel was siphoned out of the tank.

On April 20, the time had finally come and the machine was successfully lifted onto the construction site, where it was reassembled by our specialists. In a few weeks, once the work is done, the return will proceed in the same way.

09661 Hainichen / Sa.

+49 (0) 3 72 07 65 07 - 0

+49 (0) 3 72 07 65 07 - 50

info@bohrwerkzeuge.com

|bohrwerkzeuge.com